Thermoform Machine

Thermoform means “shaping with heat”. In manufacturing industry, it means shaping sheets with heat. The semi-processed thermoplastic sheet which is attached to the machine and heated up to the softening point, takes the desired shape by vacuum method.

Thermoform machines help to pack food, medical and consumer products both efficiently and economically.

Technical Information

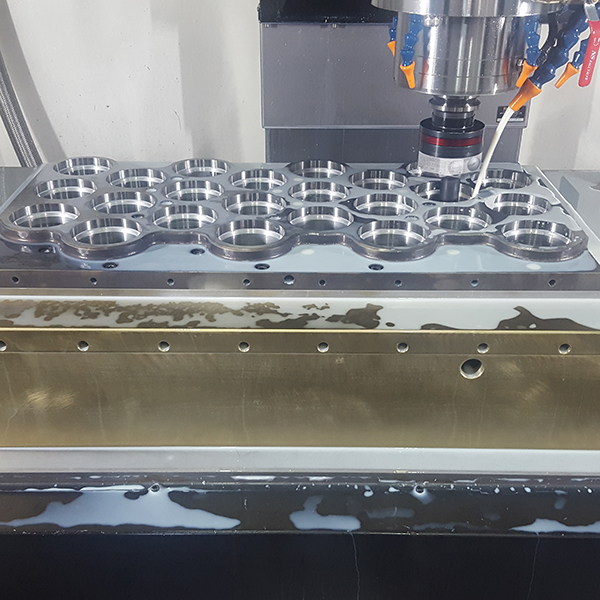

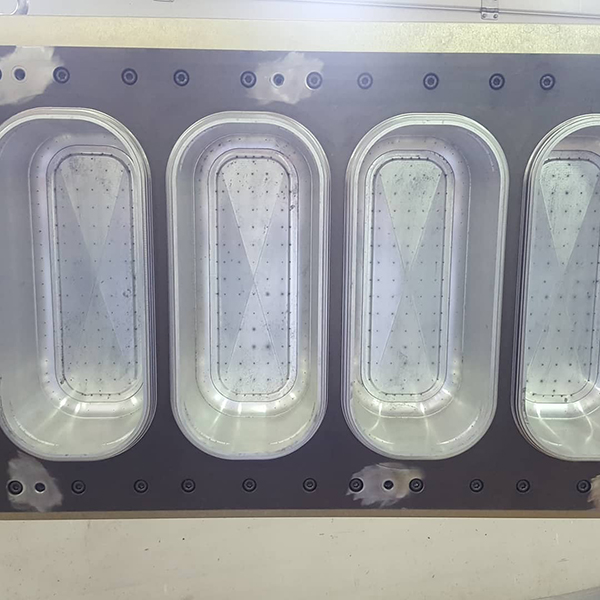

- Thermoform machines are designed for mass production to shape plastic film materials such as PP, PS, PVC, and PET using thermoform technique.

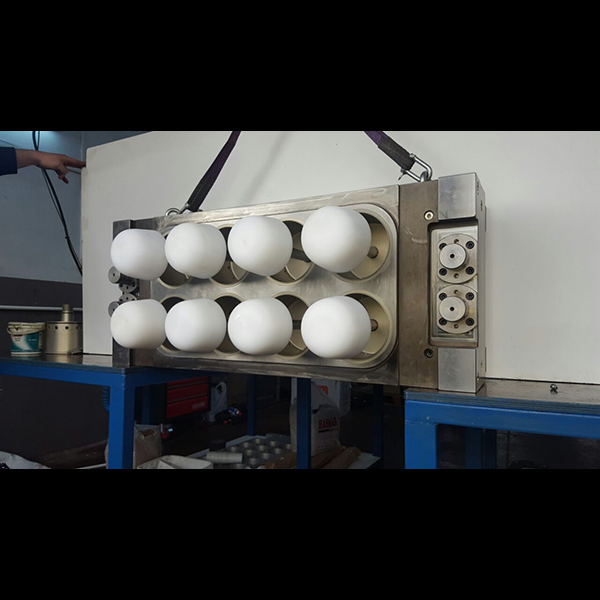

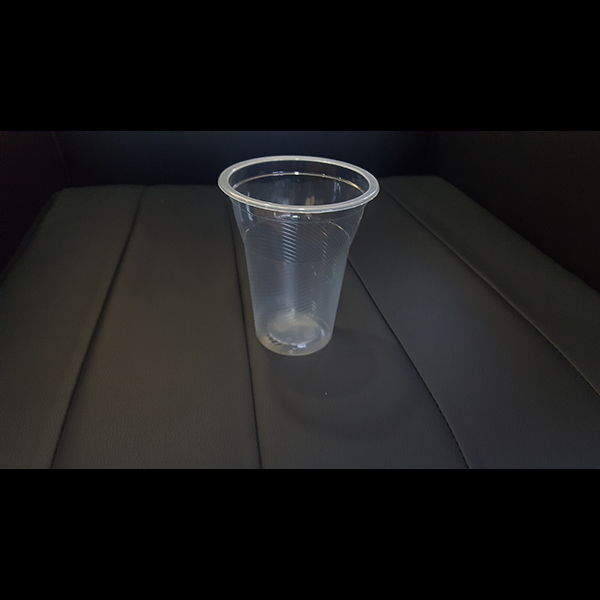

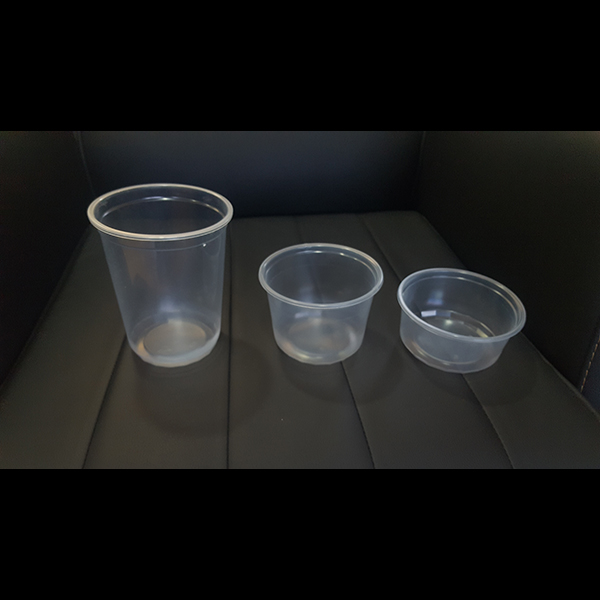

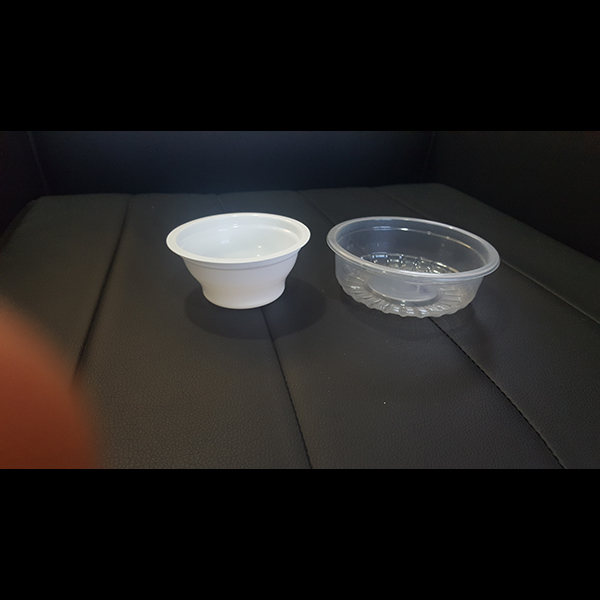

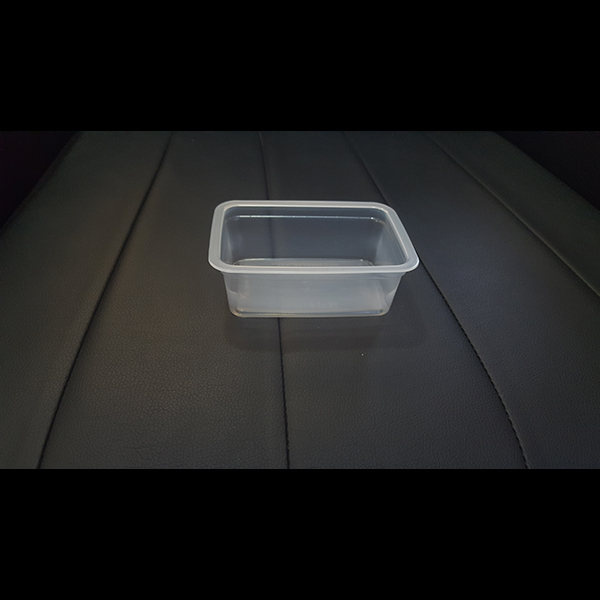

- The machine is used to produce many types of round or angular containers such as disposable plastic food containers, cups, trays, containers for yoghurt, eggs, fruit, dessert, salad, and meat.

- Thermoform machines have a wide range of uses for the food industry.

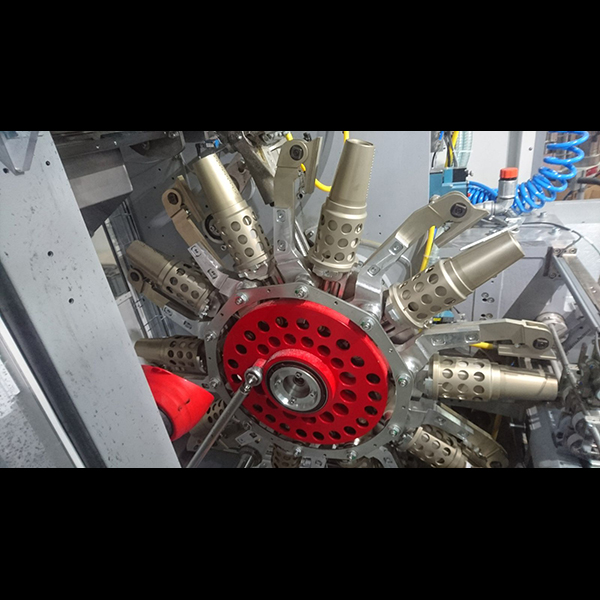

- The system consists of five station options including heating, forming, drilling, cutting, and sorting according to the containers desired to be produced. It is fully automatic and controlled by PLC.

- These stations are placed on a slide system. The positions of the sorting and cutting stations can be electrically adjusted on this sliding system.

- All parameters of operations are entered and saved to the system via the touch screen. Thus, possible errors and time losses that can be repeated in every production change are eliminated.

- The film transfer is done with a servo engine.

- Roll lifting system is pneumatic.

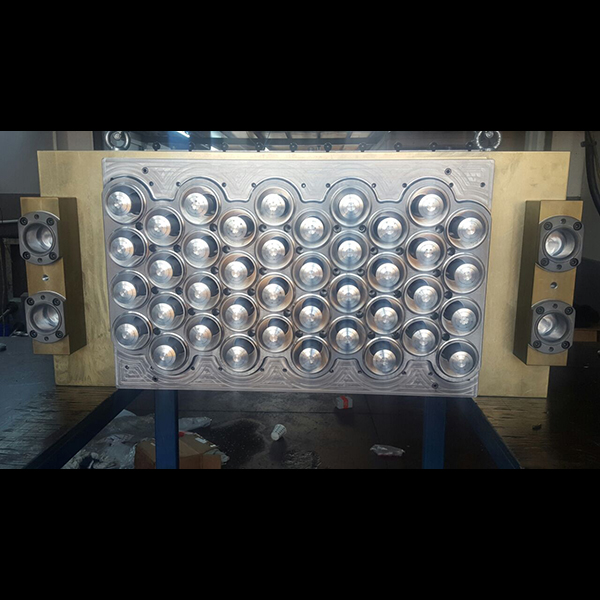

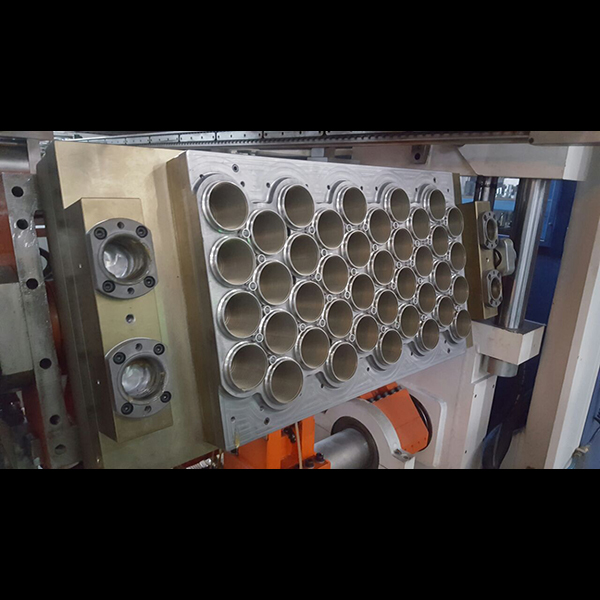

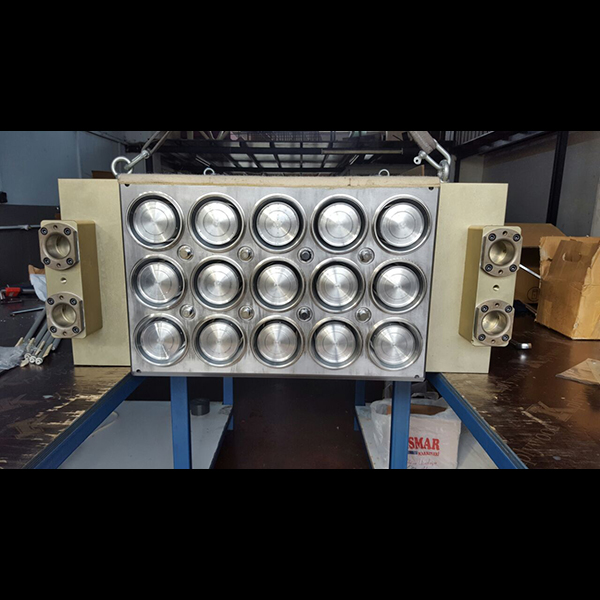

- There is a sled system in the forming station that facilitates mold attachment.

- In the sorting station, the products are sorted in numbers with the help of the vacuum system and transferred to the conveyor belt.

- Operator safety in the system is provided by electronic security barriers.

Machine Dimensions

Machine Weight

Machine Dimensions

13000 kg

11000 mm X 2800 mm X 3350 mm